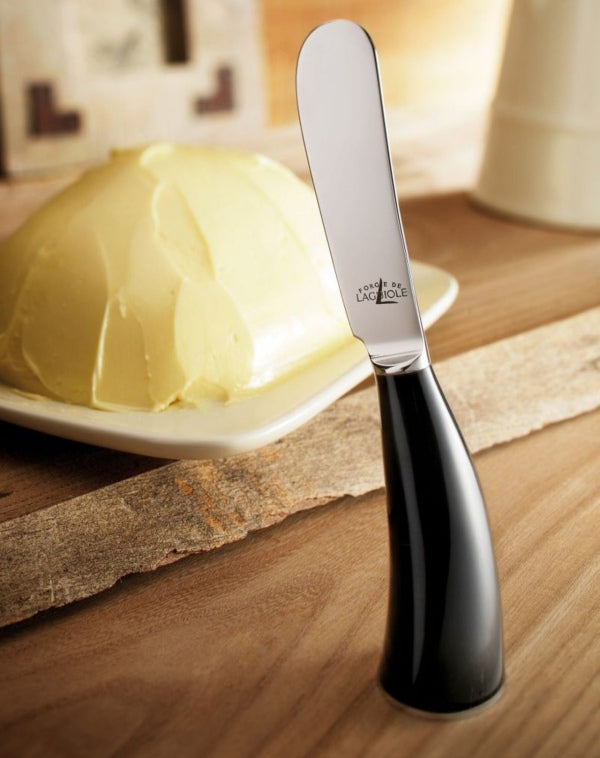

How Forge de Laguiole's blades are forged

It is rare to find a Laguiole manufacturer that produces truly forged blades. Although Forge de Laguiole is one of them, they do not use hammer forging techniques as it would make the retail price unaffordable. Instead, they use a 300-ton press to forgetheir T12 blades. T12 steel, which is exclusively made for Forge de Laguiole, is known for its durability, rust resistance, and ease of sharpening. The company's unique forging methods, coupled with tempering, create a blade with a perfect cutting edge. The steel used is sourced from the Isère region of France and is forged in-house in the village of Laguiole.